DYRKA

Transforming Creative Production for a DTC Eyewear Brand Through AI-Generated Content

Industry:

DTC Eyewear / Fashion E-Commerce

Company Size:

< 10 employees

Engagement Length:

10 weeks

Services Delivered:

AI Creative Strategy, Content Production Transformation, Campaign Execution

Overview

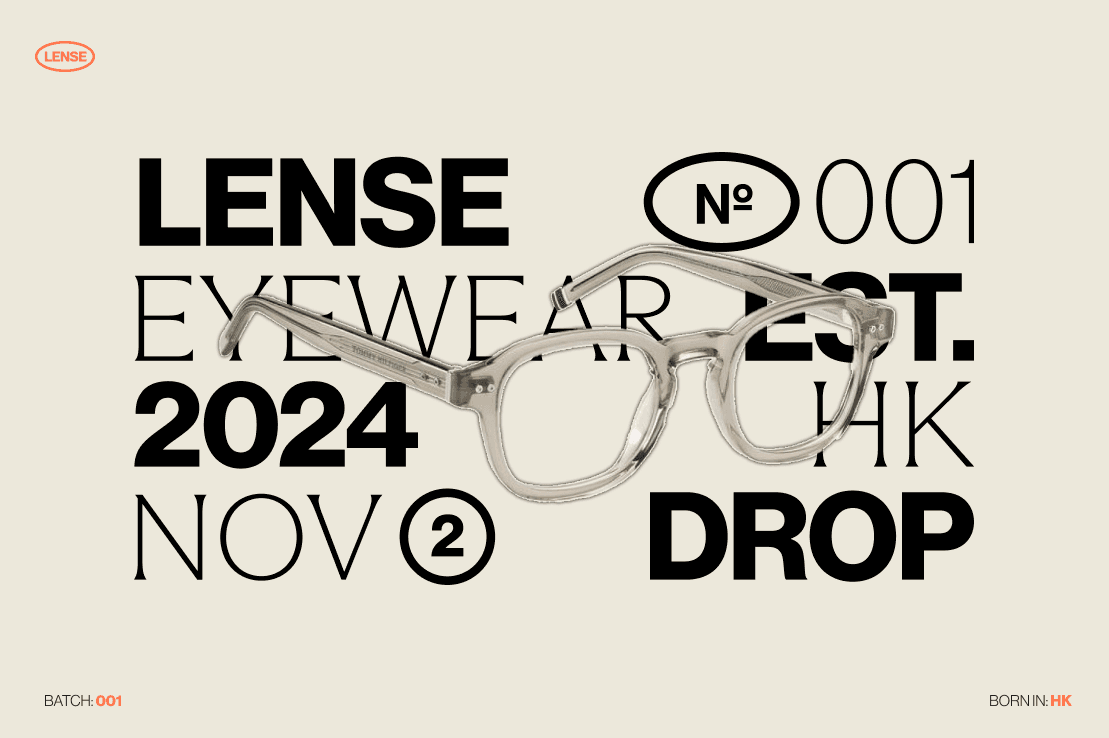

Dyrka is a direct-to-consumer eyewear brand with a strong aesthetic identity and a growing customer base. Like most lean DTC brands, its ability to produce high-quality visual content was constrained by budget, logistics, and production timelines.

Traditional look book campaigns requiring photographers, models, studios, retouchers, and art directors were cost-prohibitive at the frequency the brand needed to stay competitive. The solution wasn't to spend more. It was to rebuild how content was made entirely.

The Core Problem

Dyrka's creative output was limited not by vision, but by the cost and complexity of traditional production.

Key issues included:

High per-campaign production costs making frequent content refreshes financially unviable

Long lead times between concept and final creative assets

Dependency on external photographers, models, and studios creating scheduling bottlenecks

Limited ability to test and iterate on visual concepts before committing to full shoots

Creative velocity too low to support effective paid media testing and scaling

The brand had strong product-market fit. What it lacked was a content engine that could match its ambition without draining its budget.

Constraints & Reality Check

This was not a brand without creative direction. Dyrka already had:

A defined visual identity and brand aesthetic

Validated product demand

An engaged customer base

What it lacked was the infrastructure to produce world-class visual content at a cost and speed that made commercial sense for a sub-10 person operation.

Strategic Approach

Rather than optimizing the traditional production model, we replaced it. The entire lookbook campaign was rebuilt around AI-generated imagery using generative AI tools to produce campaign-quality visuals without photographers, models, studios, or post-production teams. This wasn't a compromise on quality. It was a fundamental upgrade to how creative production works for a lean brand.

AI Creative Production

Every image in the look book campaign was generated using AI from model selection and environment design to lighting, composition, and final output. The creative direction remained fully human-led, with AI executing at a fraction of traditional cost.

Campaign Architecture

The AI-generated content was structured as a full look book campaign, coherent, on-brand, and ready for deployment across paid media, organic social, and the website.

Iterative Testing

With production costs near zero per asset, the team could generate multiple visual directions, test concepts rapidly, and iterate without financial consequence.

Key Initiatives Implemented

Replaced traditional photography production with AI-generated look book campaign

Developed an AI content workflow enabling rapid creative iteration

Produced a full campaign asset library without a single physical shoot

Maintained brand aesthetic consistency across all AI-generated visuals

Enabled faster creative testing cycles for paid media performance

Quantitative Results

Minimum $20,000 saved per campaign versus traditional production costs

Full look book campaign delivered at a fraction of conventional timelines

Creative output capacity increased dramatically without headcount additions

Cost per creative asset reduced to near zero at the production level

Qualitative Impact

Creative decisions no longer constrained by budget or logistics

Brand team empowered to explore visual directions without financial risk

Faster time to market for campaign launches

A replicable, scalable content production model the brand can run indefinitely

Proof of concept for AI-first creative operations in DTC fashion

Dyrka didn't just run an AI-generated campaign. It proved that a small, ambitious brand can produce content that competes with brands spending ten times more by rebuilding the production model from the ground up.

Case studies